Pleasanton Building & Roofing Professionals

Get Pleasanton roofing knowledge founded on ASCE 7 wind exposure, NOAA Atlas 14 rainfall, and CRC/Title 24 compliance. We carry out laser-level structural evaluations, infrared/dye leak mapping, and moisture verification (ASTM D7877). Anticipate ember-resistant edges (CBC 7A), upgraded underlayments, and corrosion‑resistant fasteners. You'll receive definitive repair/replace decisions, CSI-coded estimates, HOA‑aligned specs, and OSHA-compliant work. Materials are vetted to UL 790, ASTM D3161/D7158, and UL 580/1897. Explore how our code-focused process shields your home year-round.

Essential Highlights

- Neighborhood Pleasanton professionals knowledgeable about warm-arid summers, moist winters, Diablo winds, and Chapter 7A ember-resistant boundaries.

- Detailed inspections: structural load configurations, hardware integrity, moisture level charting, infrared, dye testing, and hose integrity testing with image-logged discoveries.

- Reports meeting code requirements: cited CRC codes, pass or fail benchmarks, seal-stamped remarks, priority-ordered tasks, and service life projection analysis.

- Data-backed repair vs. replacement: roof deck moisture (ASTM D7877), wind uplift resistance ratings, pull-out strength of fasteners, and flashing continuity.

- Permitting and HOA coordination handled; climate-appropriate materials specified, ventilation calculated per IRC R806, and Title 24 energy standards met.

Exactly Why Regional Experience Is Important for Pleasanton Roofs

As Pleasanton sits in a microclimate zone with hot-dry summers, cool and wet winters, and periodic Diablo winds, local roofing expertise guarantees specifications correspond to real-world loads and failure modes. You need practitioners who translate wind exposure (ASCE 7), rainfall intensity (NOAA Atlas 14), and heat cycles into material, fastening, and flashing details that meet plan check and operate in service.

You'll benefit from specialists experienced with local codes, historic preservation constraints, and HOA standards, so constructions comply with setbacks, sightlines, and approved color/texture palettes. Regional contractor connections hastens supply, certifies installers, and ensures warranty-compliant sequencing. Teams concentrate on climate adaptation: upgraded underlayments, vented assemblies to control dew-point, ember-resistant edges per Chapter 7A, and corrosion-resistant fasteners. End results: fewer callbacks, stable lifecycle costs, and verified compliance.

Full-Service Roofing Inspection Services

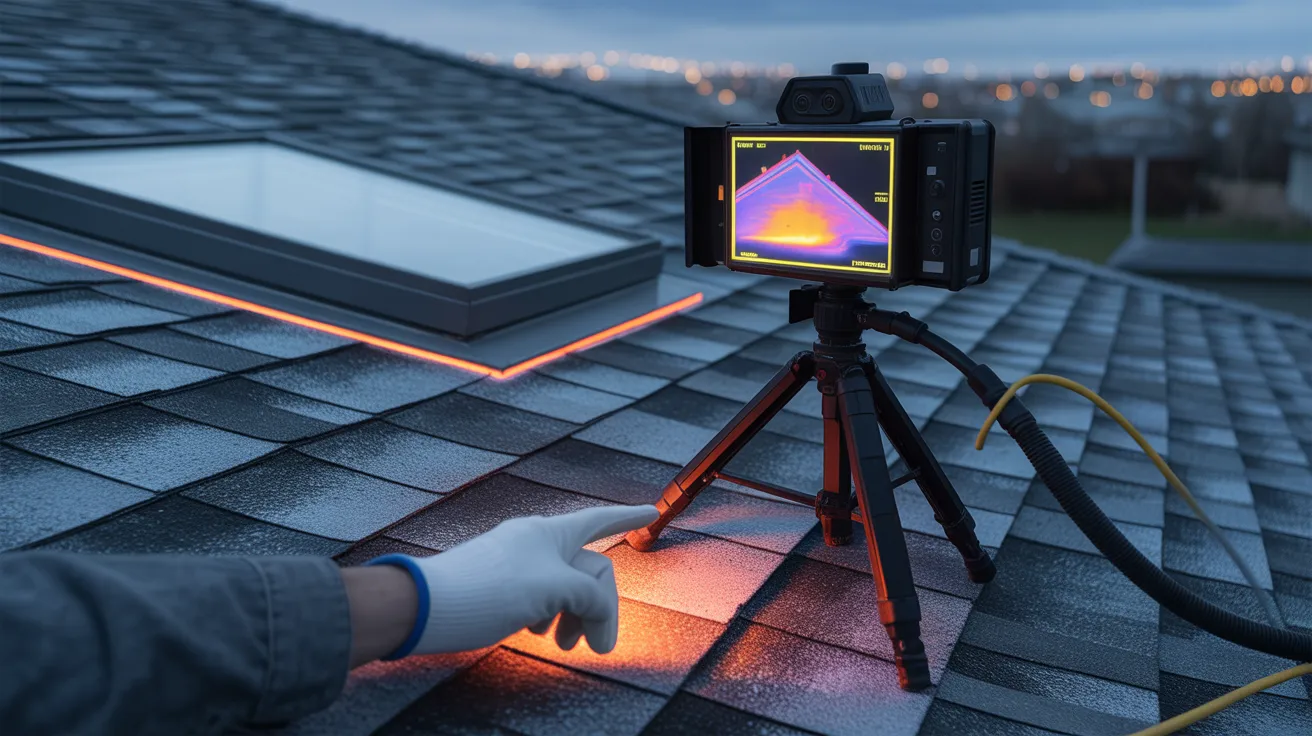

You'll get a thorough structural assessment that measures load paths, fastener integrity, membrane condition, and substrate deflection with photographically here documented findings. We apply leak detection techniques using moisture meters, infrared thermography, tracer dyes, and controlled hose testing to localize intrusion points with timestamped data. You obtain maintenance and reporting that outline prioritized repairs, service intervals, and code-compliant documentation for compliance and budgeting.

In-Depth Structural Assessment

Though each roof ages uniquely, a thorough structural assessment applies a standardized, test-driven methodology to validate load paths, member integrity, and code compliance. We provide quantified findings: we record truss geometry, measure deflection, and calculate tributary areas to validate load bearing integrity against ASCE 7 design loads. We inspect rafters, ridge beams, sheathing nailing patterns, and connection hardware, recording fastener spacing and uplift resistance per manufacturer specs.

We analyze the relationship between framing plumbness and diaphragm stiffness with indications of foundation settlement, through the use of laser levels, crack gauges, and moisture-adjusted density readings. You'll find photo-verified anomalies, section modulus evaluations for overstress, and metal connector corrosion ratings. We also assess attic ventilation ratios, insulation weight impacts, and snow/wind load histories. We deliver pass/fail criteria, corrective priorities, and stamped compliance notes.

Techniques for Detecting Leaks

Even before water appears on ceilings, we deploy a layered leak-detection protocol that pinpoints sources, validates pathways, and quantifies risk. You get a structured workflow: baseline moisture mapping, anomaly confirmation, and source pinpointing. We start with calibrated thermal imaging to reveal temperature differentials from evaporative cooling, flagging subsurface moisture beneath membranes, shingles, and flashings. Following this, we use capacitance and pin-type meters to verify saturation levels by material class.

We then use acoustic sensors to identify micro-drips and capillary flow within cavities, filtering ambient noise to identify path convergence. Dye tracing with UV additives confirms ingress points at penetrations, seams, and terminations. Finally, controlled hose testing separates assemblies in zones, tracking flow onset time, rate, and spread to correlate cause, path, and entry with high confidence.

Maintenance and Documentation

When inspection data is captured, we move into maintenance and reporting with a defined protocol that transforms findings into actionable work orders. You receive a prioritized task list with severity, location, and component IDs connected to photos and sensor logs. We codify fixes as tickets with scope, materials, labor hours, and acceptance criteria, then schedule seasonal assessments to validate remediation and prevent regression.

Our assessments follow a consistent schema: defect type, root cause hypothesis, recommended remedy, and risk score. You obtain timestamps, technician signatures, and chain-of-custody for samples. Record keeping is standardized: all artifacts reside in a searchable repository with version control, audit trails, and change logs. Metrics-MTBF, leak recurrence, and moisture deltas-drive refinements to your maintenance plan.

Storm Damage Evaluations and Insurance Support

Initiate the process by triaging storm consequences with a structured roof examination: document hail impacts, wind-lifted shingles, creased tabs, punctured underlayment, displaced flashing, and granule loss using geotagged photos and time stamps. Capture near and distant documentation photos, include slope, elevation, and compass directional markers, and log moisture readings at penetrations. Deploy an emergency tarp following OSHA fall protection and City of Pleasanton guidelines; note dimensions and fastener spacing.

Lodge insurance claims during policy notice periods; attach invoices, your inspection log, and ASTM/ICC references for damage criteria. Coordinate adjuster interaction to your evidence: schedule ladder assists, share a damage map, and request line-item scopes (Xactimate estimating or equivalent). Track payout deadlines, reserve supplements for hidden damage, and apply deductible strategies legally-never inflate line items or omit depreciation details.

System and Material Options for Roofing

You'll analyze asphalt shingles to metal panels using service life, wind uplift ratings (ASTM D3161/E1592), fire classifications (UL 790), and regional energy code impacts. You'll additionally size ventilation to satisfy IRC R806 (balanced intake/exhaust and net free area) and combine it with insulation R-values per California Title 24. With these specs, you can evaluate thermal performance, control condensation risk, and align material selection with lifecycle cost and maintenance intervals.

Asphalt versus Metal

While both systems can offer durable weatherproofing in Pleasanton's microclimate, asphalt shingles and standing-seam metal differ markedly in performance, lifecycle, and total cost of ownership. You'll typically find asphalt installed to ASTM D3462 with Class A fire ratings and optional Class H wind resistance; anticipate 20-30 years of service if installed per ICC-ES reports. Metal panels (24-26 ga) with concealed fasteners comply with UL 580/1897 wind uplift and Class A fire, often exceeding 50 years.

Metal's high solar reflectance index and cool-pigment coatings enhance energy efficiency and minimize thermal cycling. Asphalt delivers better intrinsic sound insulation, but metal with solid decking and underlayment reduces the gap. Initial cost advantages asphalt; lifecycle cost often benefits metal due to fewer replacements and lower maintenance.

Ventilation and Thermal Insulation

Choosing asphalt or metal sets the external layer, but roof effectiveness in Pleasanton hinges on how you specify ventilation and insulation as a system. You'll satisfy code and increase roof lifespan by balancing intake and exhaust. Set net free area for attic ventilation at 1:150 (or 1:300 with a Class I/II vapor retarder), split roughly 50/50 between soffit intake and ridge exhaust. Use baffled vents to block wind-driven rain and keep 1-inch clear air paths above insulation.

Indicate R-38 to R-49 attic insulation; air-seal penetrations before applying batts or blown cellulose. In mixed-dry climate Pleasanton, favor vented attics; if unvented, use code-approved spray foam at the roof deck. For crawlspace insulation, air-seal and insulate rim joists, address ground vapor, and preserve conditioned airflow.

Repair or Replace: How We Help You Decide

Because every roof ages differently, our inspectors evaluate current state before proposing repair or replacement. We obtain precise measurements: slope, deck moisture content (%, ASTM D7877), shingle granule loss (%), fastener pull-out strength (lbf), membrane seam integrity, flashing continuity, and leak mapping via infrared scanning and tracer dye analysis. You receive a definitive evaluation matrix aligned to California Residential Code and manufacturer specifications.

We evaluate remaining service life using defect density and local weather loads, then conduct a cost benefit analysis over the roof's life cycle. If targeted repairs can restore watertightness and code compliance with ≥3 years projected service, we detail repair scope and materials. If systemic failures exist- decaying substrate, extensive UV embrittlement, or ventilation-related curl–we recommend replacement to eradicate recurrent risk and sunk maintenance costs.

Honest Quotes and Work Schedules

Look for line-item estimates and Gantt-based schedules that you can review. You'll see scope, quantities, unit costs, and labor hours linked to CSI codes, so upfront pricing is transparent. We attach assumptions, exclusions, and change-order thresholds, eliminating scope creep. Each task features predecessors, resource loading, and buffer logic, yielding realistic timelines you can trace back to weather data and crew availability.

We apply timestamps to each revision, keep a versioned expense log, and deliver variance reports (baseline compared to current). You will obtain start/finish dates, critical path visibility, and float calculations, so schedule risk is explicit. We match payment milestones to earned value, not promises, and provide progress updates with photo evidence. If unknowns emerge, we issue a quantified impact analysis before you authorize any adjustments.

Safety Standards and Workmanship Guarantees

When crews mobilize, we implement OSHA 29 CFR 1926 Subpart M fall protection, ANSI/ASSE Z359 tie-off standards, and ASTM D226/D7158 material specs to manage risk and confirm compliance. You'll see guardrails, warning lines, and 100% tie-off with inspected anchors rated per Z359. Worker PPE includes hard hats, cut-resistant gloves, ANSI Z87.1 eye protection, and ASTM F2413 boots; respirators are utilized per 1910.134 when adhesives or particulates warrant.

We record pre-task plans, ladder inspections to 1926.1053, and hot-work permits with fire watch. Fastener patterns follow manufacturer ESRs and FM 4470 approvals; underlayments comply with ASTM D226 and wind ratings per D7158 classification.

Our quality assurance connects to standards-compliant installation and verified torque and pull-out testing. We provide written coverage duration terms, transferability, and claim response SLAs.

Maintenance Programs to Increase Roof Lifespan

With safety controls and workmanship standards locked in, a structured maintenance plan maintains performance and warranty value. You'll execute seasonal inspections aligned with Pleasanton's precipitation and UV cycles: spring/fall assessments for wind uplift, fastener torque, sealant elasticity (ASTM D4586/D793), and membrane punctures; summer IR scans to identify latent moisture; winter examinations for flashing movement and underlayment exposure. Execute gutter maintenance quarterly: clear debris, verify slope (1/16-1/8 in./ft), seal seams, and verify downspout discharge ≥5 ft from foundations to stop fascia rot and ice dams.

Catalog each task with dated photos, readings (humidity meter %MC), and a deficiency list ranked by risk. Replace compromised shingles, secure popped fasteners, reseal penetrations, and prune overhanging limbs. Calibrate maintenance intervals by roof age, material class, and exposure rating.

What to Expect on Installation Day and Beyond

Before the team shows up, you'll see a pre-start checklist: permit posted, utility lines located, staging area taped, and weather window verified (≤20% precip probability, sustained winds <20 mph). Anticipate neighbor introductions to coordinate parking, noise windows, and debris control. Upon arrival, the crew photographs existing conditions, sets fall protection per OSHA 1926.501, and installs perimeter tarps and magnetic mats. The tear-off process advances by slope; decking is inspected and replaced to meet CRC R803. Underlayment, flashing components, and penetrations follow manufacturer specs and Title 24 cool-roof requirements where applicable.

You will review and approve ventilation numbers, fastener placement patterns, and shingle batch numbers. Daily QC logs record nailing depth and valley information. Final walkthrough includes drone imagery, warranty registration, and post inspection cleaning: magnet sweep, gutter flush, and driveway blow-off.

Questions & Answers

Are There Financing or Payment Plan Options for Roofing Projects?

Yes-you can use Flexible Financing with consistent Monthly Payments. You select APR, term length, and down payment; we create an amortization schedule and itemized cost breakdown. We provide soft-credit prequalification, no prepayment penalties, and ACH or card autopay. Standard options: 0% promo periods, fixed-rate terms (12 to 120 months), and staged draws tied to project milestones. We verify identity, income, and project scope, then issue a detailed, code-style contract with exact payment dates.

Are There Eco-Friendly Disposal Practices for Old Roofing Materials?

Yes. You can establish eco-friendly disposal through material sorting, recycling programs, and regenerative disposal streams. Segregate asphalt shingles for shingle-to-pavement repurposing, metals for smelting, wood for biomass, and plastics for HDPE recycling. Require haulers with documented chain-of-custody and landfill diversion reports. Mandate LEED-compliant practices, contaminated material isolation, and dust/particulate controls. Employ on-site containers with labeled streams, verify processor certifications, and audit diversion rates (>75%). Record data in disposal manifests for compliance.

Do You Collaborate With Solar Installers During Roofing Work?

Yes. You can activate Solar coordination by synchronizing tear-off, dry-in, and underlayment milestones with Installer scheduling windows. Share array layout, conduit paths, rafter maps, and attachment specs in a joint pre-construction meeting. You'll pre-place flashed standoffs, dedicated homeruns, and roof penetrations per NEC/IBC. Sequence: dry-in → standoff install → waterproofing → final roofing → PV mounting. Use shared Gantt updates, change-order gates, and photo QA to ensure code compliance and reduce rework.

What's Your Approach to Pets and Yard Access During Projects?

We require secured yard access and controlled pet management. Before work, you'll confine indoor pets to secured rooms and transfer outdoor pets clear of access paths and debris zones. Please provide gate codes/lock combinations, note sprinkler lines, and flag fragile landscaping. We stage materials on hardscape only, install temporary barriers as needed, and log gate status daily. You'll confirm waste bin placement and cleanup windows. Deviations require written approval. Noncompliance may pause work for safety.

How Do You Handle Unforeseen Structural Concerns Uncovered During the Project?

When unforeseen conditions emerge, you adjust swiftly. Think strategically, act decisively: you trigger a structured workflow-immediate structural assessment, document findings (photos, load-path notes), and quantify risk. You suspend affected scopes, execute repair prioritization by safety, weatherproofing, and critical-path impact. You generate a change order with costs, code citations, and timeline adjustments. You establish interim stability (bracing, tarps), procure approvals/permits as required, then implement fixes per IRC/IBC standards and manufacturer details. You validate with reinspection.

Closing Remarks

You've observed how local expertise, rigorous inspections, and data-backed decisions converge like thoroughly-tested code deploying cleanly to production. When storms occur, we'll triage, document, and optimize your claim path. You'll assess material specs, life-cycle costs, and failure modes, then choose repair or replacement with confidence. Expect straightforward estimates, reliable timelines, OSHA-aligned safety, and workmanship guarantees. With scheduled maintenance, your roof's uptime remains high. On install day, every fastener, flashing, and seam aligns-tight, validated, and ready for years of reliable service.